Annealing. Surface Treatment. Normalizing

Annealing

Whether cold forging hot or warm forging, after the material is shaped with a high pressure forging punch machine, the internal stress in the material also increases. The next step in the process is to relieve internal stress in the material for subsequent processing.

In the metal machining world, annealing is a typical way to reduce stress. The method involves keeping the material within a certain temperature variation along with a time delay control. This technique can efficiently reduce the internal stress of the material. Chian Hsing, as a major combined forging factory, provides various annealing processes applied to different conditions.

※ Normal soften annealing:crucible annealing furnace,continuous annealing furnace.

※ Full annealing: continuous annealing furnace.

※ Spheroidizing annealing:3-ton Toyo furnace, 6-ton Sanyo Spheroidizing furnace.

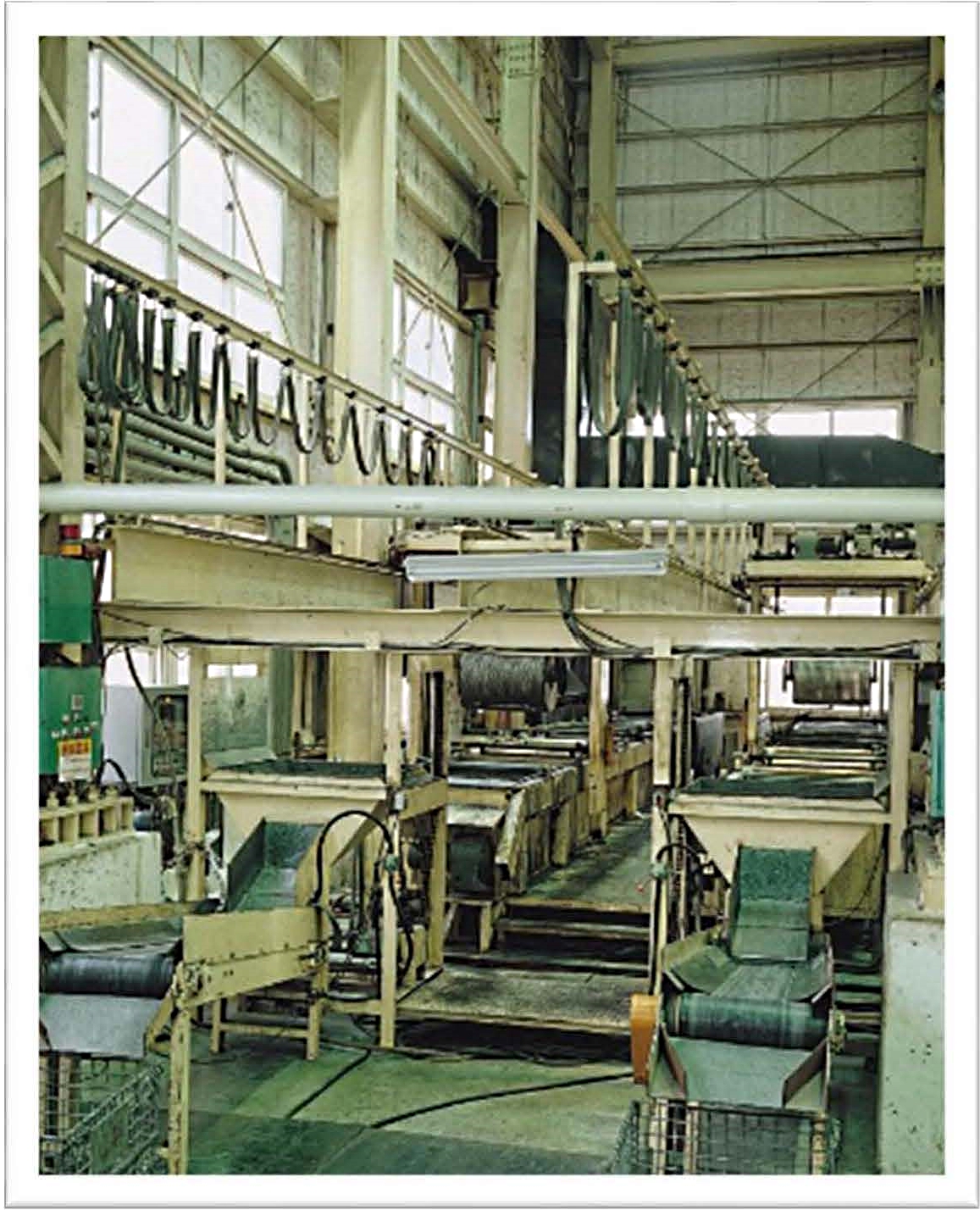

Surface Treatment

Before proceeding with cold forging on a work piece, such as pulling, shaping, twisting, etc., the surface friction factor must be reduced first. The effects are as follows.

※ To reduce the friction factor between material and mold when forging.

※ To protect the life of the mold and ensure the accuracy of the product dimensions.

※ To increase the flowing speed of the material in the forming areas.

※ To make the surface of forged product smooth and even to satisfy the processes, such as wire drawing,pipe drawing, cold

forging shaping, etc., combining with spraying lubricant during shaping to make shaping most effective.

Normalization

Normalization occurs when steel is cooled in the air for natural cooling after being heated to above 900℃.

For forged steel, when heated to the temperature required by hot forging, crystalline grain coarsening occurs, and then due to the shape variation by high pressure or the temperature variation before and after the process, problems such as crystalline grain unevenness or carbides partially coagulating will occur. The purpose of normalization is to eliminate the above unwanted structures and improve the mechanical features of steel. Especially for forged products for automobiles, the forged product with normalization can be machined much easier than the forged product without normalization. This can increase the efficiency of machining and prolong the life of tools for customers.